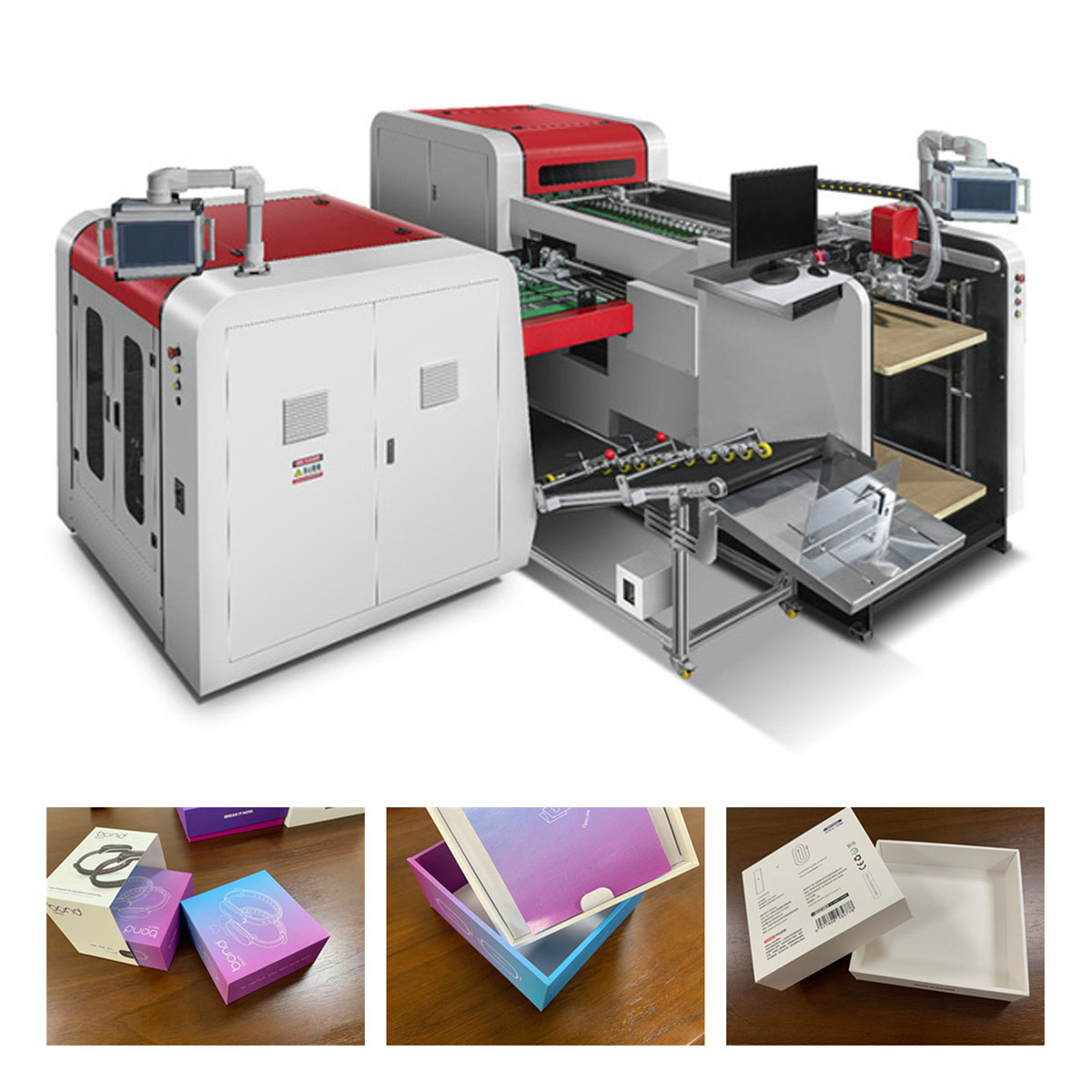

SAILI Mašine za izradu luksuznih kutija

SLQ-600S

Mašina za ‘grooving’ papira i kartona, za pravljenje oštrih ivica na kutijama

Ova mašina pravi kanal V oblika koji omogućava da se papir ili lepenka sa viju pod uglom od 90 stepeni i formiraju idealno pštru liniju savijanja na kutijama. Mašina radi zasecanje u oba smera tako da nakon obrade tabak izlazi potpuno spreman za kaširanje ili lepljenje. Upotrebaljava se za luksuzne kutije, kutije za nakit, kutiej za telefone i tehničke uređaje.

| Veličina materijala – 1. korak | 180-600 mm |

| Veličina materijala – 2. korak | 180-500 mm |

| Preciznost zasecanja | ±0.1 mm |

| Ugao zasecanja | 90-115° Adjustable |

| Debljina materijala | 200-350 g |

| Brzina rada | 80 kom/min (300 × 300 mm) |

| Broj linija zasecanja – 1. korak | 6 |

| Broj linija zasecanja – 1. korak | 6 |

| Ulaganje | FEIDA |

| Snaga | 13.5 KW |

| Težina | 5200 kg |

| Dimenzije | 3076 x 3253 x 1880 mm |

| Material Size of 1st Step | 180-600 mm |

| Material Size of 2nd Step | 180-500 mm |

| Grooving Line Accuracy | ±0.1 mm |

| Grooving Angle | 90-115° Adjustable |

| Material Thickness | 200-350 g |

| Working Speed | 80 pcs/min (300 × 300 mm) |

| Grooving Lines of 1st Step | 6 lines |

| Grooving Lines of 2nd Step | 6 lines |

| Feeding Way | FEIDA feeding |

| Power | 13.5 KW |

| Weight | 5200 kg |

| Dimension | 3076 x 3253 x 1880 mm |

KLQ-600

Automatska dvosmerna mašina za zasecanje papira

Ova mašina je namenjena za izradu V zareza na više tipova materijala – sivoj lepenci, kartonu, MDF i istalih debelih tipova papira. Unapređena je brzina rada i produktivnost. Isecanje se radi u oba smera i dobija se tabak spreman za savijanje i lepljenje.

| Veličina materijala – 1. korak | 100-450 mm (D), 100-600 mm (Š) |

| Veličina materijala – 2. korak | 100-600 mm (D), 100-600 mm (Š) |

| Preciznost zasecanja | ±0.1 mm |

| Ugao zasecanja | 90-130° podesivo |

| Debljina materijala | 1.0-3.0 mm |

| Brzina rada | 130 kom/min (200 × 200 mm) |

| Broj linija zasecanja – 1. korak | 8 linija (2 kolone) |

| Broj linija zasecanja – 1. korak | 4 linije (1 kolona) |

| Ulaganje | kaiše, |

| Izlaz otpada | Na kraju koraka 2 |

| Snaga | 6.5 KW |

| Težina | 3200 kg |

| Dimenzije | 3900 x 3680 x 1445 mm |

| Material Size of 1st Step | 100-450 mm (L), 100-600 mm (W) |

| Material Size of 2nd Step | 100-600 mm (L), 100-600 mm (W) |

| Grooving Line Accuracy | ±0.1 mm |

| Grooving Angle | 90-130° Adjustable |

| Material Thickness | 1.0-3.0 mm |

| Working Speed | 130 pcs/min (200 × 200 mm) |

| Grooving Lines of 1st Step | 8 lines (2 rows) |

| Grooving Lines of 2nd Step | 4 lines (1 row) |

| Feeding Way | Belt feeding |

| Waste Delivery Way | Both come out from End Part of 2 steps |

| Power | 6.5 KW |

| Weight | 3200 kg |

| Dimension | 3900 x 3680 x 1445 mm |

SLG-600

Automatic Bidirectional Grooving Machine

This machine is newly invented based on the experience of Automatic cross grooving machine. It’s include automatic function of crosswise corner cutting + crosswise grooving + 90° switchover + lengthwise corner cutting +lengthwise grooving + four corner removing.It’s suitable for various of Lid and base boxes,such as Mobile phone boxes,shoe boxes, cosmetic boxes, rigid boxes, etc.Improve product quality, and production efficiency, saves labor and morespace.

| Material Size | 150 x 150-500 x 500 mm |

| Grooving Line Accuracy | ±0.1 mm |

| Grooving Angle | 90-130° Adjustable |

| Material Thickness | 1.5-3.0 mm |

| Working Speed | 150 pcs/min (200×200 mm) |

| Secant Overhead Length | ≤5 mm |

| Secant Length | 15-120 mm |

| Grooving Line Quantity | 4 lines of 1st Step, 4 lines of 2nd Step |

| Secant Part | Controlled by PLC |

| Power | 8.0 KW |

| Weight | 3000 kg |

| Dimension | 6100 x 2870 x 1559 mm |